Exactly How Expert Product Packaging Maker Fixing Services Reduce Downtime and Increase Productivity

Expert packaging maker repair solutions are essential in decreasing downtime and enhancing performance through specialized diagnostics and prompt interventions. The implications of such services prolong past prompt repair services-- unboxing the more comprehensive effect on functional efficiency exposes crucial understandings into long-term productivity approaches - packaging machine repair service.

Value of Timely Services

Timely repair work of product packaging machines are important for maintaining functional performance in any manufacturing environment. When machinery breakdowns or breaks down, it can lead to significant interruptions in production lines, leading to increased downtime and lost earnings. The longer a product packaging equipment continues to be out of order, the better the impact on general efficiency, possibly causing hold-ups in satisfying orders and diminishing consumer contentment.

In enhancement to the immediate monetary implications, delayed fixings can lead to much more comprehensive damages to the machinery. Components that are not dealt with without delay can wear away even more, needing more costly repair work or total replacements, which might have been stayed clear of with prompt intervention. In addition, regular upkeep and prompt repair services can enhance the life-span of product packaging devices, guaranteeing that they operate at optimal efficiency degrees.

Buying expert packaging equipment repair solutions is important for mitigating these threats. An aggressive approach to repair services not just keeps manufacturing schedules however also cultivates a society of dependability within the company. By focusing on timely repair services, organizations can keep their affordable edge, maximize source appropriation, and ultimately enhance their profits via improved functional performance.

Knowledge in Diagnostics

Efficient diagnostics not only assist in swift identification of issues but likewise improve the total dependability of packaging operations. By carrying out extensive analyses, specialists can assess the health of critical components, guaranteeing that also minor abnormalities are attended to without delay. This focus to information reduces the risk of unforeseen breakdowns, which can lead to costly downtime.

In addition, expert diagnostics give important understandings right into functional fads, allowing companies to make enlightened choices concerning equipment upgrades or adjustments. By leveraging these understandings, companies can optimize their product packaging processes, bring about enhanced efficiency and efficiency. Inevitably, spending in diagnostic competence is crucial for companies looking for to maintain smooth procedures and maintain high requirements of top quality in their product packaging processes.

Preventive Upkeep Perks

Precautionary maintenance matches specialist diagnostics by proactively addressing potential problems before they manifest right into major troubles. By executing an organized preventive upkeep program, firms can significantly decrease the danger of unforeseen maker failings, thus minimizing costly downtime. Regular assessments, cleansing, and this content components replacement assistance make sure that packaging machinery operates at ideal effectiveness.

One of the crucial benefits of precautionary upkeep is its capability to prolong the life-span of devices. By frequently keeping equipment, companies can stay clear of the intensifying impacts of wear and tear that commonly cause major fixings or substitutes. packaging machine repair service. This not only conserves capital yet also improves the total reliability of manufacturing procedures

Furthermore, preventive maintenance contributes to improved safety problems within the work environment. By identifying and remedying prospective dangers before they intensify, companies develop a safer atmosphere for their staff members. This proactive strategy not only shields employees but also promotes a society of obligation and alertness.

Personalized Solution Solutions

Recognizing the distinct demands of each organization, customized service options for product packaging machine repair offer customized approaches that enhance functional effectiveness. These solutions are created to deal with details difficulties encountered by various markets, ensuring that machine downtime look at this site is lessened and performance is maximized.

Expert repair service solutions start with a comprehensive evaluation of a business's packaging procedures. By understanding the certain machinery included and the needs of the production atmosphere, professionals can develop a tailored maintenance and repair strategy. This may consist of specialized click here to read training for in-house staff, the execution of anticipating maintenance technologies, or the arrangement of specialized support during peak production times.

Additionally, personalized solutions can integrate versatile solution arrangements that line up with a firm's functional schedule, enabling repair work to be executed throughout off-peak hours. By prioritizing the unique needs of each organization, these bespoke services ensure that fixings are not only reliable however likewise seamlessly integrate right into existing workflows.

Inevitably, the emphasis on modification allows firms to optimize their product packaging procedures, resulting in enhanced dependability and efficiency of equipment, which is vital for preserving competitive benefit in today's busy market.

Effect On Overall Efficiency

Personalized service options not just address details fixing needs however additionally play a significant function in boosting overall functional performance. By giving targeted interventions, expert packaging maker repair work solutions straight decrease the frequency and duration of tools failings. This positive technique ensures that assembly line continue to be functional, decreasing disturbances that can cause pricey downtime.

Moreover, effective repair work services contribute to smoother operations, as well-maintained equipment runs at optimum efficiency degrees. When machines function correctly, the quality of packaged products boosts, causing less issues and much less rework. This enhancement not just increases efficiency however also strengthens customer complete satisfaction.

Furthermore, regular maintenance and quick response times from repair service professionals cultivate a society of dependability within the company. Employees can concentrate on their key jobs instead of bothering with possible tools breakdowns. Consequently, the overall throughput of the production process rises, allowing companies to meet need better.

Ultimately, the tactical investment in specialist fixing solutions equates to improved effectiveness throughout all functional aspects, ensuring that companies can adapt and thrive in an open market. This harmony between upkeep and efficiency is crucial for long-lasting success.

Final Thought

To conclude, specialist packaging equipment fixing solutions play an essential function in reducing downtime and improving efficiency within producing environments. Prompt repair work, expert diagnostics, and precautionary upkeep add to the dependability of equipment, while tailored solution remedies address certain functional requirements. The advancing effect of these solutions results in enhanced general efficiency, enabling organizations to maintain manufacturing routines, support product quality, and efficiently satisfy market needs. Purchasing such services inevitably drives continual operational success.

Alana "Honey Boo Boo" Thompson Then & Now!

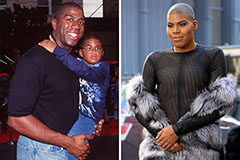

Alana "Honey Boo Boo" Thompson Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!